ANSI B16.5 Class 300 Welding Neck Flanges

India’s Leading ANSI B16.5 Alloy Steel Class 300 Weld Neck Flanges Supplier in india, BS4504 Welding Neck Flange at Low Price, Buy Stainless Steel ANSI B16.5 Class 300 Weld Neck Flange, ANSI B16.5 Industrial Weld Neck Flange PN16 Manufacturer & Supplier in India.

Kanak Steel & Engg Co. is a prominent exporter and manufacturer of ANSI B16.5 Class 300 Welding Neck Flanges, which may be as nicely pretty trouble-unfastened to put in and remove.

Made by means of the usage of outstanding great of uncooked cloth with distinctly urbane machines, its miles pretty acknowledged for its excessive great, zero-defects and advanced performance. It is a welding method used to enrol in components which might be nearly parallel and do now no longer overlap. They are very a great deal identified for his or her hovering tensile strength, balance and unique alloy composition. Meanwhile, Monel Alloy ANSI B16.5 Class 300 Welding Neck Flanges may be being made up with extraordinary grades of widespread tiers and meet its provisos within the direction of country wide and global standards.

The maximum extensive utility for such flanges is in warmness exchangers and heater coils. They are located in braces, in which they may be joined together within the organization of joint flanges. The predominant characteristic of such Hastelloy Alloy ANSI B16.5 Class 300 Welding Neck Flanges is to downsize the road from a kindly proportioned to a much less extensive pipe size, and this in reality outcomes in a higher glide pressure. They also are being linked at the water pump strains with the aid of the solitary application of getting rid of the air blocks. They are made from an intensive variety of pipe substances that encompass excessive and coffee yield alloys.

Meanwhile, using such flanges improves the route and glide of the run in piping system. On the alternative hand, it generally permits plumbing to be associated with a few different plumbing or as a minimum to a water heater. Nickel Alloy ANSI B16.5 Class 300 Welding Neck Flanges are made by means of the usage of advanced widespread great of uncooked cloth collectively with excessive and complex sort of machines. As they may be made from by means of the usage of excessive widespread great of steel, they may be anti-corrosive, nonpartisan and additionally continue to exist in robust temperature conditions.

Largest Manufacturer & Supplier of ANSI B16.5 Class 300 Welding Neck Flange Threaded, B16.5 Class 300 WNRF Flanges Jis B2220, EN1092-1 Weld Neck Flange Supplier, ANSI B16.5 Class 300 Weld Neck Flanges in Mumbai, India.

Specification Of ANSI B16.5 Class 300 Weld Neck Flange

| ANSI B16.5 Class 300 Weld Neck Flange Standards | ANSI B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ANSI Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JIS B2220, BS1560-3.1, API7S-15, API7S-43, API 605, EN1092 |

|---|---|

| ANSI B16.5 Class 300 Weld Neck Flange Pressure Rating ANSI | Class 300 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ANSI B16.5 ANSI B16.5 Class 300 Weld Neck Flange Size Chart | 1/2″ (15 NB) to 48″ (1200 NB) DN10~DN5000 |

| ANSI B16.5 Class 300 Weld Neck Flange Pressure Calculation in DIN | 6 Bar, 10Bar, 16Bar, 25Bar, 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ANSI B16.5 Class 300 Weld Neck Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

| Special design | As per your drawing

AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of | ANSI, DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. ANSI B16.5 Class 300 Weld Neck Flange : -BS Flange, EN Flange, API 6A Flanges, ANSI Flanges, ANSI Flanges, DIN Flanges, EN1092-1 Flanges, UNI Flanges, JIS/ KS Flanges, BS4504 Flanges, GB Flanges, AWWA C207 Flanges, GOST Flanges, PSI Flangse

|

| ANSI B16.5 Class 300 Weld Neck Flange Uses & application |

|

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Manufacturing ANSI B16.5 Stainless Steel Class 300 Welding Neck Flanges Specification

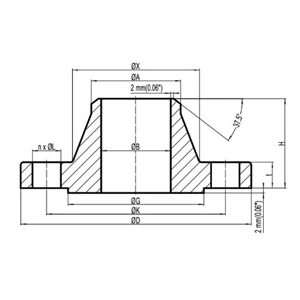

| Nominal Pipe Size | Outside Diameter (O) | Thickness (T) | Raised Face Diameter (R) | Length Thru Hub (Y) | Point of Weld (A) | Hub Diameter (X) | Bore (B) | Approximate Weight (lbs) | Bolt Circle (C) | Number of Holes | Diameter of Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 3.75 | 0.56 | 1.38 | 2.06 | 0.84 | 1.50 | 0.62 | 2 | 2.63 | 4 | 0.63 |

| 3/4 | 4.63 | 0.63 | 1.69 | 2.25 | 1.05 | 1.88 | 0.82 | 3 | 3.25 | 4 | 0.75 |

| 1 | 4.88 | 0.69 | 2.00 | 2.44 | 1.32 | 2.13 | 1.05 | 4 | 3.50 | 4 | 0.75 |

| 1 1/4 | 5.25 | 0.75 | 2.50 | 2.56 | 1.66 | 2.50 | 1.38 | 5 | 3.88 | 4 | 0.75 |

| 1 1/2 | 6.13 | 0.81 | 2.88 | 2.69 | 1.90 | 2.75 | 1.61 | 7 | 4.50 | 4 | 0.88 |

| 2 | 6.50 | 0.88 | 3.63 | 2.75 | 2.38 | 3.31 | 2.07 | 9 | 5.00 | 8 | 0.75 |

| 2 1/2 | 7.50 | 1.00 | 4.13 | 3.00 | 2.88 | 3.94 | 2.47 | 12 | 5.88 | 8 | 0.88 |

| 3 | 8.25 | 1.13 | 5.00 | 3.13 | 3.50 | 4.63 | 3.07 | 15 | 6.63 | 8 | 0.88 |

| 3 1/2 | 9.00 | 1.19 | 5.50 | 3.19 | 4.00 | 5.25 | 3.55 | 18 | 7.25 | 8 | 0.88 |

| 4 | 10.00 | 1.25 | 6.19 | 3.38 | 4.50 | 5.75 | 4.03 | 25 | 7.88 | 8 | 0.88 |

| 5 | 11.00 | 1.38 | 7.31 | 3.88 | 5.56 | 7.00 | 5.05 | 32 | 9.25 | 8 | 0.88 |

| 6 | 12.50 | 1.44 | 8.50 | 3.88 | 6.63 | 8.13 | 6.07 | 42 | 10.63 | 12 | 0.88 |

| 8 | 15.00 | 1.63 | 10.63 | 4.38 | 8.63 | 10.25 | 7.98 | 67 | 13.00 | 12 | 1.00 |

| 10 | 17.50 | 1.88 | 12.75 | 4.63 | 10.75 | 12.63 | 10.02 | 91 | 15.25 | 16 | 1.13 |

| 12 | 20.50 | 2.00 | 15.00 | 5.13 | 12.75 | 14.75 | 12.00 | 140 | 17.75 | 16 | 1.25 |

| 14 | 23.00 | 2.13 | 16.25 | 5.63 | 14.00 | 16.75 | 13.25 | 180 | 20.25 | 20 | 1.25 |

| 16 | 25.50 | 2.25 | 18.50 | 5.75 | 16.00 | 19.00 | 15.25 | 250 | 22.50 | 20 | 1.38 |

| 18 | 28.00 | 2.38 | 21.00 | 6.25 | 18.00 | 21.00 | 17.25 | 320 | 24.75 | 24 | 1.38 |

| 20 | 30.50 | 2.50 | 23.00 | 6.38 | 20.00 | 23.13 | 19.25 | 400 | 27.00 | 24 | 1.38 |

| 22 | 33.00 | 2.63 | 25.25 | 6.50 | 22.00 | 25.25 | 21.25 | 465 | 29.25 | 24 | 1.63 |

| 24 | 36.00 | 2.75 | 27.25 | 6.63 | 24.00 | 27.63 | 23.25 | 580 | 32.00 | 24 | 1.63 |

ANSI B16.5 Class 300 Weld Neck Flanges Dimensions & Weight Chart

| ANSI B16.5 300lb/sq.in. Flange WNRF | |||||||||||

| ø | D | b | g | m | a | J* | h | k | Holes | l | Kg. |

| 1/2″ | 95,2 | 14,3 | 34,9 | 38,1 | 21,3 | 15,7 | 52,4 | 66,7 | 4 | 15,9 | 0,900 |

| 3/4″ | 117,5 | 15,9 | 42,9 | 47,6 | 26,7 | 20,8 | 57,1 | 82,5 | 4 | 19,0 | 1,500 |

| 1″ | 123,8 | 17,5 | 50,8 | 54,0 | 33,5 | 26,7 | 61,9 | 88,9 | 4 | 19,0 | 1,900 |

| 1 1/4″ | 133,3 | 19,0 | 63,5 | 63,5 | 42,2 | 35,1 | 65,1 | 98,4 | 4 | 19,0 | 2,600 |

| 1 1/2″ | 155,6 | 20,6 | 73,0 | 69,8 | 48,3 | 40,9 | 68,3 | 114,3 | 4 | 22,2 | 3,300 |

| 2″ | 165,1 | 22,2 | 92,1 | 84,1 | 60,3 | 52,6 | 69,8 | 127,0 | 8 | 19,0 | 3,600 |

| 2 1/2″ | 190,5 | 25,4 | 104,8 | 100,0 | 73,1 | 62,7 | 76,2 | 149,2 | 8 | 22,2 | 5,400 |

| 3″ | 209,5 | 28,6 | 127,0 | 117,5 | 88,9 | 78,0 | 79,4 | 168,3 | 8 | 22,2 | 7,400 |

| 3 1/2″ | 228,6 | 30,2 | 139,7 | 133,3 | 101,6 | 90,2 | 81,0 | 184,1 | 8 | 22,2 | 8,900 |

| 4″ | 254,0 | 31,7 | 157,2 | 146,0 | 114,3 | 102,4 | 85,7 | 200,0 | 8 | 22,2 | 11,900 |

| 5″ | 279,4 | 34,9 | 185,7 | 177,8 | 141,2 | 128,3 | 98,4 | 234,9 | 8 | 22,2 | 16,000 |

| 6″ | 317,5 | 36,5 | 215,9 | 206,4 | 168,4 | 154,2 | 98,4 | 269,9 | 12 | 22,2 | 20,200 |

| 8″ | 381,0 | 41,3 | 269,9 | 260,3 | 219,1 | 202,7 | 111,1 | 330,2 | 12 | 25,4 | 31,000 |

| 10″ | 444,5 | 47,6 | 323,4 | 320,7 | 273,0 | 254,5 | 117,5 | 387,3 | 16 | 28,6 | 44,300 |

| 12″ | 520,7 | 50,8 | 381,0 | 374,6 | 323,8 | 304,8 | 130,2 | 450,8 | 16 | 31,7 | 64,000 |

| 14″ | 584,2 | 54,0 | 412,7 | 425,4 | 355,6 | 336,5 | 142,9 | 514,3 | 20 | 31,7 | 88,000 |

| 16″ | 647,7 | 57,1 | 469,9 | 482,6 | 406,4 | 387,3 | 146,0 | 571,5 | 20 | 34,9 | 113,000 |

| 18″ | 711,2 | 60,3 | 533,4 | 533,4 | 457,2 | 438,1 | 158,7 | 628,6 | 24 | 34,9 | 134,000 |

| 20″ | 774,7 | 63,5 | 584,2 | 587,4 | 508,0 | 488,9 | 161,9 | 685,8 | 24 | 34,9 | 171,000 |

| 22″ | 838,2 | 66,7 | 641,2 | 641,2 | 558,8 | 539,7 | 165,1 | 742,9 | 24 | 41,3 | 195,000 |

| 24″ | 914,4 | 69,8 | 692,1 | 701,7 | 609,6 | 590,5 | 168,3 | 812,8 | 24 | 41,3 | 238,000 |

B16.5 Class 300 Welding Neck Flange Material

| Carbon Steel ANSI B16.5 Class 300 Weld Neck Flange | ASTM/ANSI A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ANSI SA105, A105N, ASTM A350 LF2 / ANSI SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Stainless Steel ANSI B16.5 Class 300 Weld Neck Flange | ASTM/ANSI A/SA182 F304, F304L, F316, F316L, ASTM/ANSI A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Alloy Steel ANSI B16.5 Class 300 Weld Neck Flange | ASTM A182 / ANSI SA182 F5, F9, F11, F12, F22, F91 |

| Titanium ANSI B16.5 Class 300 Weld Neck Flange | ASTM B381 / ANSI SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper ANSI B16.5 Class 300 Weld Neck Flange | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel ANSI B16.5 Class 300 Weld Neck Flange | ASTM / ANSI SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass ANSI B16.5 Class 300 Weld Neck Flange | 3602 / 2604 / H59 / H62 / etc. |

| Inconel ANSI B16.5 Class 300 Weld Neck Flange | ASTM B564 / ANSI SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Class 300 Weld Neck Flange |

| Hastelloy ANSI B16.5 Class 300 Weld Neck Flange | ASTM B564 / ANSI SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel ANSI B16.5 Class 300 Weld Neck Flange | ASTM B564 / ANSI SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 ANSI B16.5 Class 300 Weld Neck Flange | ASTM B462 / ANSI SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium ANSI B16.5 Class 300 Weld Neck Flange | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel ANSI B16.5 Class 300 Weld Neck Flange | ASTM B564 / ANSI SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex ANSI B16.5 Class 300 Weld Neck Flange | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex ANSI B16.5 Class 300 Weld Neck Flange | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy ANSI B16.5 Class 300 Weld Neck Flange | ASTM B564 / ANSI SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 Smo ANSI B16.5 Class 300 Weld Neck Flange | ASTM A182 / ANSI SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic ANSI B16.5 Class 300 Weld Neck Flange | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other ANSI B16.5 Class 300 Weld Neck Flange material | Tin bronze, Aluminum bronze, Lead bronze |

Weight Chart of ANSI B16.5 Class 300 Weld Neck Flange

| ANSI B16.5 WELD NECK FLANGES WEIGHT (KGS) | ||||||||||||||||||

| Pipe Size |

150# | 300# | 600# | 900# | 1500# | 2500# | ||||||||||||

| WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | WN | S/O | B/K | |

| 1/2” | 0.7 | 0.4 | 0.5 | 0.8 | 0.7 | 0.8 | 0.9 | 0.8 | 0.8 | 2.1 | 1.8 | 1.9 | 2.1 | 1.8 | 1.9 | 3.2 | 3 | 3 |

| 3/4” | 0.8 | 0.7 | 0.8 | 1.4 | 1.2 | 1.2 | 1.6 | 1.4 | 1.4 | 2.7 | 2.4 | 2.7 | 2.7 | 2.4 | 2.7 | 3.6 | 4 | 4.5 |

| 1” | 1.1 | 0.8 | 0.9 | 1.7 | 1.4 | 1.5 | 1.9 | 1.7 | 1.7 | 3.9 | 3.6 | 3.7 | 3.9 | 3.6 | 3.7 | 5.4 | 5 | 5 |

| 1.1/4” | 1.5 | 1.2 | 1.3 | 2.2 | 1.8 | 2 | 2.6 | 2.1 | 2.4 | 4.5 | 4.1 | 4.3 | 4.5 | 4.1 | 4.3 | 7.8 | 8 | 8 |

| 1.1/2” | 1.8 | 1.4 | 1.6 | 3.2 | 2.7 | 2.9 | 3.6 | 3.1 | 3.4 | 6.2 | 5.4 | 5.9 | 6.2 | 5.4 | 5.9 | 11.5 | 11 | 11 |

| 2” | 2.7 | 2.2 | 2.6 | 3.6 | 3.2 | 3.5 | 4.7 | 3.9 | 4.4 | 11.3 | 10.5 | 11.3 | 11.3 | 10.5 | 11.3 | 19 | 17 | 17 |

| 2.1/2” | 4.4 | 3.5 | 4.1 | 5.4 | 4.5 | 5.3 | 4.8 | 5.4 | 6.8 | 16.3 | 15.8 | 16 | 16.3 | 15.8 | 16 | 24 | 25 | 25 |

| 3” | 5.2 | 3.8 | 5.1 | 7.3 | 5.9 | 7.2 | 8.7 | 7.3 | 8.9 | 15 | 12.3 | 16.8 | 21 | 21.5 | 19.5 | 42.6 | 38 | 39 |

| 3-1/2” | 6.4 | 5 | 6.5 | 8.9 | 7.5 | 9.2 | 11.6 | 9 | 12.7 | – | – | – | – | – | – | – | – | – |

| 4” | 7.5 | 5.6 | 7.5 | 11.8 | 10 | 12.2 | 18.4 | 16.5 | 18.6 | 24 | 23.2 | 24.5 | 31.8 | 31 | 33 | 64 | 58 | 60 |

| 5” | 9.2 | 6.5 | 9.2 | 16 | 12.5 | 16 | 31 | 28.5 | 30.8 | 38.5 | 37.5 | 39.5 | 59 | 58.8 | 60 | 111 | 95 | 101 |

| 6” | 11.0 | 8.1 | 11.8 | 20.2 | 16.5 | 22 | 37 | 36.2 | 38 | 50 | 48.3 | 51.5 | 72 | 74 | 75 | 171 | 146 | 156 |

| 8” | 18.4 | 13 | 20.4 | 31.2 | 25.5 | 36 | 54.5 | 51.5 | 62.2 | 85 | 75 | 89 | 124 | 112 | 125 | 261 | 220 | 242 |

| 10” | 25.5 | 18.4 | 31 | 44.3 | 35 | 55 | 98.5 | 76.2 | 102 | 123 | 110 | 131 | 207 | 184 | 215 | 485 | 420 | 465 |

| 12” | 37 | 28.5 | 47 | 63.5 | 52 | 82.5 | 105 | 89.5 | 132 | 168 | 146 | 187 | 306 | 264 | 316 | 698 | 590 | 665 |

| 14” | 51 | 37.5 | 60 | 86 | 73 | 108 | 150 | 102 | 158 | 198 | 172 | 224 | 416 | – | – | – | – | – |

| 16” | 61.5 | 44.5 | 61 | 112 | 88 | 139 | 177 | 150 | 225 | 225 | 192 | 259 | 567 | – | – | – | – | – |

| 18” | 71.5 | 54 | 93 | 141 | 115 | 178 | 228 | 180 | 285 | 318 | 272 | 383 | 736 | – | – | – | – | – |

| 20” | 85 | 72 | 127 | 173 | 139 | 228 | 285 | 231 | 365 | 376 | 330 | 482 | 929 | – | – | – | – | – |

| 24” | 119 | 95 | 190 | 248 | 212 | 350 | 372 | 330 | 532 | 680 | 632 | 905 | 1504 | – | – | – | – | – |

ANSI B16.5 #300 Weld Neck Flange Schedule Chart

| WELDING NECK FLANGES BORES (in inchines) | ||||||||||||||

| Nom Pipe Size |

Outside Diam |

Sched 10 |

Sched 20 |

Sched 30 |

Std. Wall |

Sched 40 |

Sched 60 |

Extra Strong |

Sched 80 |

Sched 100 |

Sched 120 |

Sched 140 |

Sched 160 |

Double Extra Strong |

| 1/2” | 0.840 | 0.674 | – | – | 0.622 | 0.622 | – | 0.546 | 0.546 | – | – | – | 0.464 | 0.252 |

| 3/4” | 1.050 | 0.884 | – | – | 0.824 | 0.824 | – | 0.742 | 0.742 | – | – | – | 0.612 | 0.434 |

| 1” | 1.315 | 1.097 | – | – | 1.049 | 1.049 | – | 0.957 | 0.957 | – | – | – | 0.815 | 0.599 |

| 1.1/4” | 1.660 | 1.442 | – | – | 1.380 | 1.380 | – | 1.278 | 1.278 | – | – | – | 1.160 | 0.896 |

| 1.1/2” | 1.900 | 1.682 | – | – | 1.610 | 1.610 | – | 1.500 | 1.500 | – | – | – | 1.338 | 1.100 |

| 2” | 2.375 | 2.157 | – | – | 2.067 | 2.067 | – | 1.939 | 1.939 | – | – | – | 1.687 | 1.503 |

| 2.1/2” | 2.875 | 2.635 | – | – | 2.469 | 2.469 | – | 2.323 | 2.323 | – | – | – | 2.125 | 1.771 |

| 3” | 3.500 | 3.260 | – | – | 3.068 | 3.068 | – | 2.900 | 2.900 | – | – | – | 2.624 | 2.300 |

| 3-1/2” | 4.000 | 3.760 | – | – | 3.548 | 3.548 | – | 3.364 | 3.364 | – | – | – | – | 2.728 |

| 4” | 4.500 | 4.260 | – | – | 4.026 | 4.026 | – | 3.826 | 3.826 | – | 3.624 | – | 3.438 | 3.152 |

| 5” | 5.563 | 5.295 | – | – | 5.047 | 5.047 | – | 4.813 | 4.813 | – | 4.563 | – | 4.313 | 4.063 |

| 6” | 6.625 | 6.357 | – | – | 6.065 | 6.065 | – | 5.761 | 5.761 | – | 5.501 | – | 5.187 | 4.897 |

| 8” | 8.625 | 8.329 | 8.125 | 8.071 | 7.981 | 7.981 | 7.813 | 7.625 | 7.625 | 7.437 | 7.187 | 7.001 | 6.813 | 6.875 |

| 10” | 10.750 | 10.420 | 10.250 | 10.136 | 10.020 | 10.020 | 9.750 | 9.750 | 9.562 | 9.312 | 9.062 | 8.750 | 8.500 | 8.750 |

| 12” | 12.750 | 12.390 | 12.250 | 12.090 | 12.000 | 11.938 | 11.626 | 11.750 | 11.374 | 11.062 | 10.750 | 10.500 | 10.126 | 10.750 |

| 14” | 14.000 | 13.500 | 13.376 | 13.250 | 13.250 | 13.124 | 12.812 | 13.000 | 12.500 | 12.124 | 11.814 | 11.500 | 11.188 | – |

| 16” | 16.000 | 15.500 | 15.376 | 15.250 | 15.250 | 15.000 | 14.688 | 15.000 | 14.312 | 13.938 | 13.564 | 13.124 | 12.812 | – |

| 18” | 18.000 | 17.500 | 17.376 | 17.124 | 17.250 | 16.876 | 16.500 | 17.000 | 16.124 | 15.688 | 15.250 | 14.876 | 14.438 | – |

| 20” | 20.000 | 19.500 | 19.250 | 19.000 | 19.250 | 18.812 | 18.376 | 19.000 | 17.938 | 17.438 | 17.000 | 16.500 | 16.062 | – |

| 24” | 24.000 | 23.500 | 23.250 | 22.876 | 23.250 | 22.624 | 22.062 | 23.000 | 21.562 | 20.938 | 20.376 | 19.876 | 19.312 | – |

| 30” | 30.000 | 29.376 | 29.000 | 28.750 | 29.250 | – | – | 29.000 | – | – | – | – | – | – |

| 36” | 36.000 | 35.376 | 35.000 | 34.750 | 35.250 | 34.500 | – | 35.000 | – | – | – | – | – | – |

| 42” | 42.000 | – | – | – | 41.250 | – | – | 41.000 | – | – | – | – | – | – |

Dimension Tolerance Class 300 Welding Neck Flanges

| Outside Diameter | When O is 24″ or less. When O is over 24″. |

±0.06″ ±0.12″ | ±1.6 mm | ±3.2 mm |

| Diameter of Contact Face | 0.06″ (1.6 mm) raised face. 0.25″ (6.4 mm) raised face. |

±0.03″ ±0.02″ | ±0.8 mm | ±0.5mm |

| Diameter of Hub at Point of Welding | NPS 5 and smaller. NPS 6 and larger. |

+0.09″, -0.03″ +0.16″, -0.03″ | +2.4 mm, -0.8mm | +4.0 mm, -0.8 mm |

| Inside Diameter | NPS 10, 12, 18, 20 and larger. | +0.03″ +0.06″ +0.12″, -0.06″ | +0.8 mm +1.6 mm | +3.2 mm, -1.6 mm |

| Diameter of Hub at Base | Hub Base is 24″or less. Hub Base is over 24″. |

+0.06″ +0.12″ | +1.6 mm | +3.2 mm |

| Thickness | NPS 18 and smaller. NPS 20 and larger. |

+0.12″ +0.19″ | +3.2 mm | +4.8 mm |

| Drilling and Facings | Bolt circle diameter Bolt Hole Spacing | ±0.06″ ±0.03″ | ±1.6 mm | ±0.8 mm |

| Eccentricity of Bolt Circle and Facing | NPS 2 1/2 and smaller. NPS 3 and larger. |

±0.03″ ±0.06″ | ±0.8 mm | ±1.6 mm |

| Length Through Hub | NPS 10 and smaller. NPS 12 and larger. |

±0.06″ ±0.12″ | ±1.6 mm | ±3.2 mm |

Types of ANSI B16.5 Alloy Steel Class 300 Weld Neck Flanges We Supply

| ANSI B16.5 300LB WN Flange Supplier in Mumbai | 300lb Weld Neck Flange Manufacturer in India |

| ANSI B16.5 Class 300 Weld Neck Flange Din 2527 | ANSI B16.5 Class 300 Weld Neck Flange Din En 1092-1 Supplier |

| ANSI B16.5 Class 300 Weld Neck Flange Pn 60 | ANSI B16.5 #300 Weld Neck Flange CF8M |

| ANSI B16.5 #300 Weld Neck Flanges Din 2629 Supplier | BS4504 PN16 Class 300 WNRF Flanges |

| Class 300 EN1092-1 WNRF Flanges | ANSI B16.5, SCH 40 Class 300 WNRF Flanges |